Developed jointly by Elliott and Tri-Sen, the Gemini compressor performance monitor is a comprehensive, focused suite of software and enabling hardware for continuous monitoring, evaluation, and analysis of critical industrial compressor performance and associated auxiliary support systems.

%20r1.0.png)

Gemini Overview

The Gemini compressor performance monitoring system is a comprehensive compressor-focused suite of software and enabling hardware that augments your plant's predictive/proactive maintenance strategy.

It includes:

-

Elliott's custom-designed compressor performance comparison and evaluation

-

Advanced vibration analysis

-

Remote compressor and auxiliaries controls monitoring (RCM).

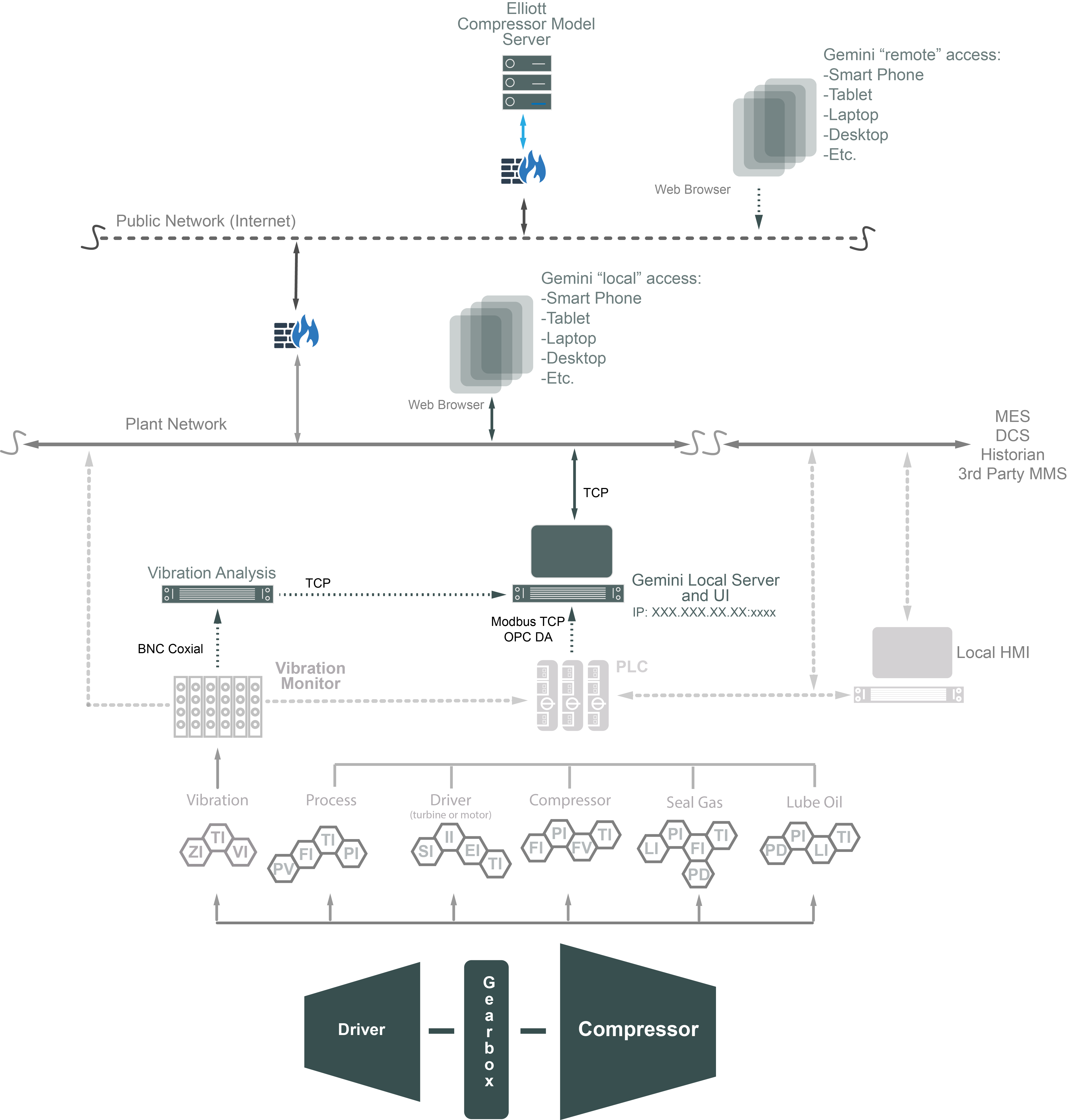

The Gemini compressor performance monitor collects high-resolution compressor data by connecting to the compressor controls programmable logic controller (PLC) and the compressor vibration monitoring system. The collected data is stored in an "Edge" database, accessed by the Gemini application software, and presented in contextually relevant, easy-to-understand graphics.

You connect to the Gemini application software in a similar way you might visit a webpage; by typing in the Gemini IP address into a web browser navigation bar.

The website-type interface allows multiple users (with the appropriate security credentials) to connect to the Gemini application at any given time without having to install any special software (apart from one of the standard web browsers.)

FEATURES

- Intuitive website-like interface (no client software required apart from internet browser)

- Elliott custom compressor model (digital twin)

- Compressor performance evaluation

- Custom process interface model

- Advanced vibration analysis interface

- Integrated system dashboard

- Remote controls monitor

- Configurable alarming with push notification

- Single integrated database (with a configurable update - 500msec to 5 minutes)

- Modbus TCP communications interface

- Two-factor user-credential-authentication to prevent unauthorized access

- Multi-level password protection/access (Admin, Engineer, User, etc.)

- Simple licensing

Solution Hardware Specifications

- Processor: 2.2GHz or faster that supports SSE2

- Number of cores: 2+

- RAM: 8GB or higher

- Hard disk space: 500GB or more

- Network Adapters: Dual RJ45

- Display resolution: 1920x1080 (CPMS supports full HD)

- Power 120-240vac (UPS recommended)

Solution Software Specifications

- Windows 10 or later

- Internet browser to access the Gemini software (Google Chrome, Microsoft Edge, Mozilla Firefox)

Gemini Compressor Digital Twin

The Gemini Compressor Digital Twin application provides a contextual and graphical representation of the deviation (and change in deviation) in the compressor’s predicted to actual performance for any given set of process conditions, using real-time or historical data.

FEATURES

-

Elliott custom compressor model (digital twin)

-

Compressor performance evaluation

-

Custom process interface model

-

Integrated system dashboard

-

Configurable alarming with push notification

-

Single integrated database (with configurable update - 500msec to 5 minutes)

-

Modbus TCP communications interface

-

OPC DA interface

-

Simple licensing

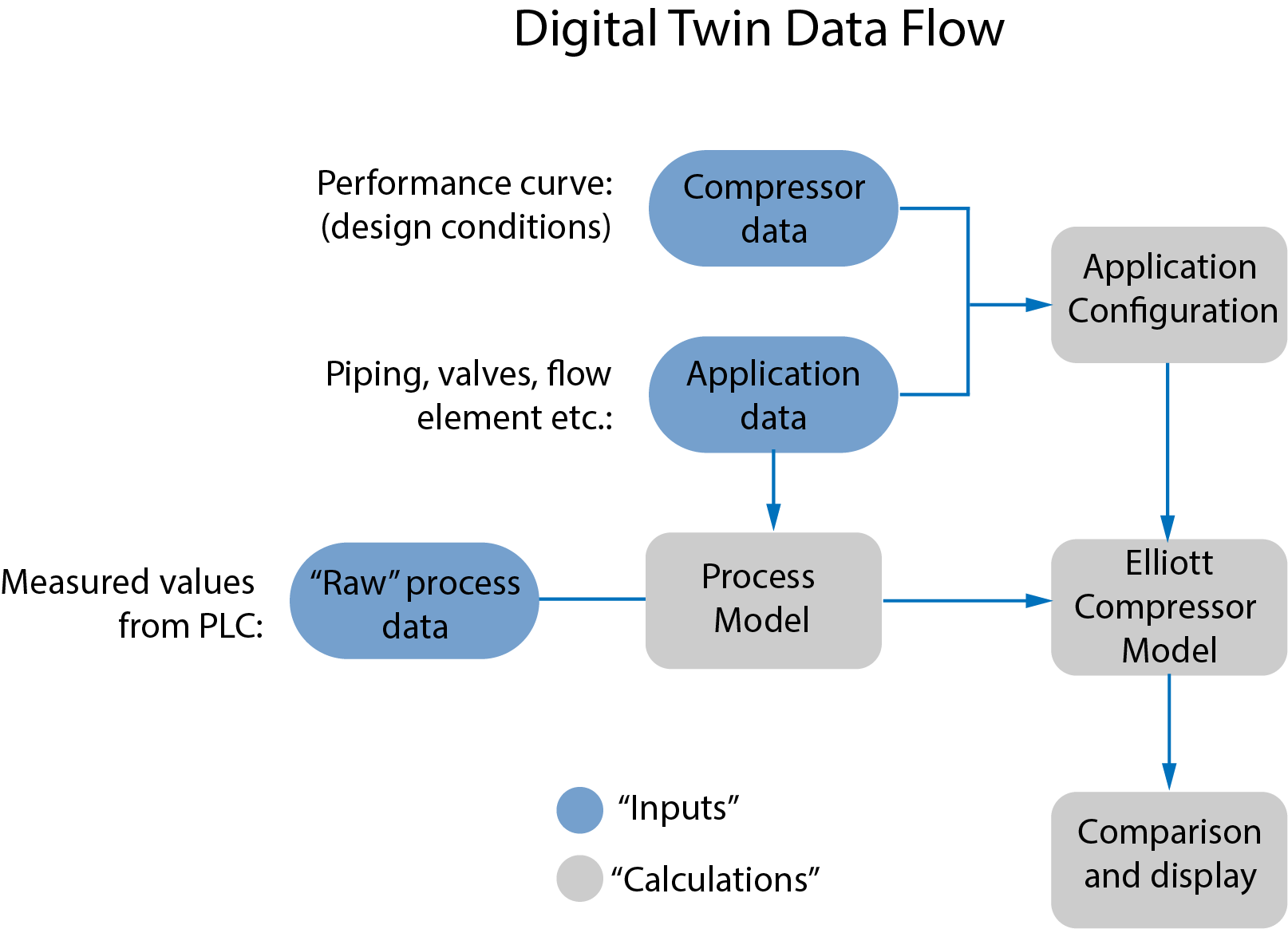

Gemini Compressor Digital Twin Data Flow

The Gemini compressor digital twin application evaluates the compressor performance by first calculating predicted compressor outputs for current process conditions.

It uses the Elliott compressor performance maps, instrumented and modeled process data, application data, and an Elliott custom compressor model (specific for the compressor and application).

The predicted performance value is then compared and evaluated against the actual compressor performance. Deviations in actual compressor performance vs. predicted compressor performance are represented graphically. If push notification is enabled and a change in deviation exceeds a configurable threshold, an SMS or email notification is sent to the appropriate plant personnel.

Gemini Compressor Models

There are two compressor models available within the Gemini compressor performance monitor: the Elliott compressor model and the local compressor model. The Elliott compressor model is the actual model used when designing and performance testing the compressor. Access to the Elliott model requires an internet connection. The local compressor model is built into the digital twin application.

For the Elliott compressor model selection (maximum fidelity), the compressor design data necessary to calculate the expected performance is integral to the Elliott compressor model.

Compressor design performance data for the local model is entered manually into the compressor digital twin application, using the Elliot compressor performance curve data.

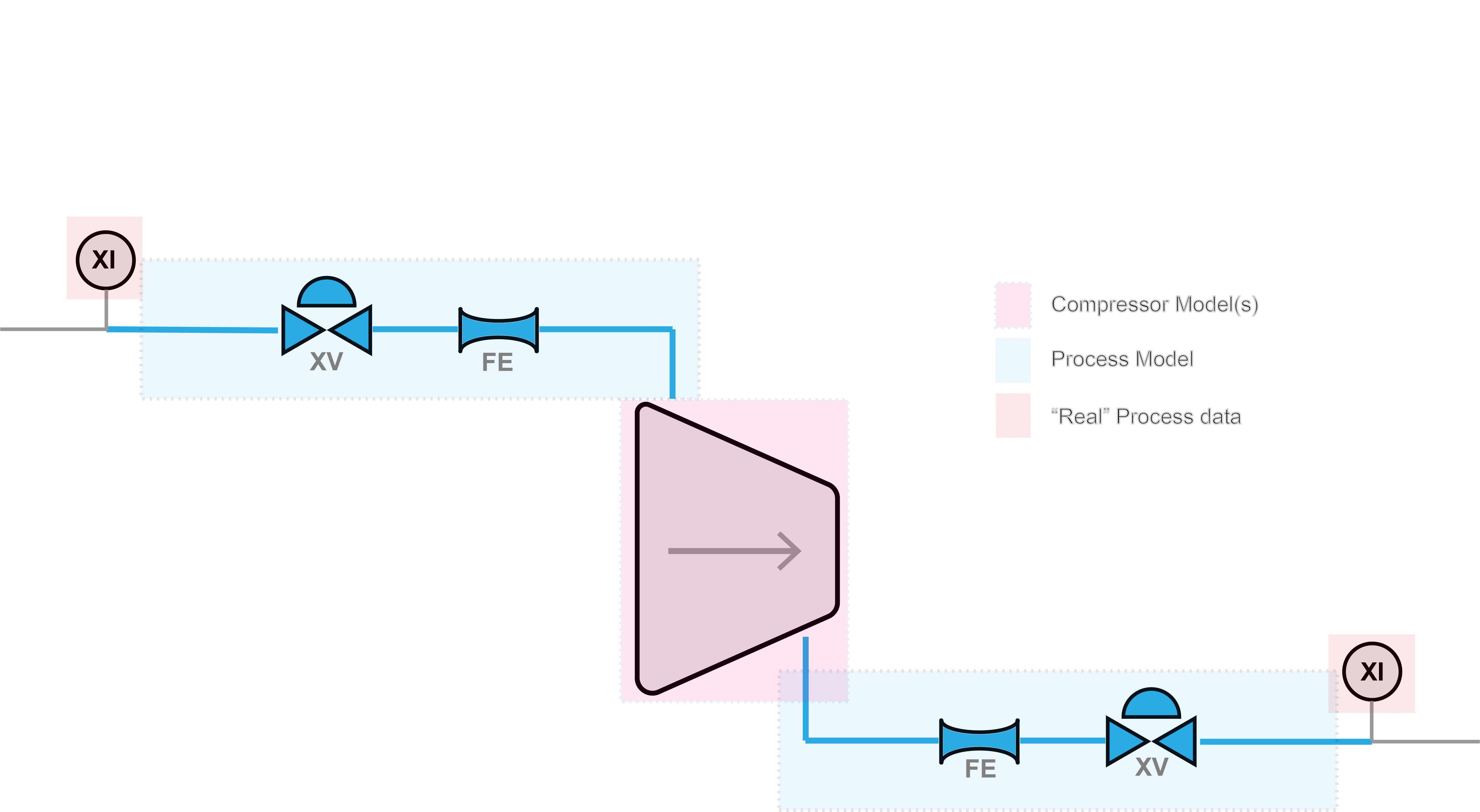

Gemini Process Model

Many times, process instrumentation doesn't account for flow elements, block or control valves, or the last/first section of piping that flanges up to the compressor.

We refer to these exclusions as "instrument gaps" around the compressor. These instrument gaps can have a significant effect on the suction and discharge pressures the compressor is physically working with.

In order to maximize the accuracy of the process data sent to the compressor models, the Gemini compressor digital twin calculates pressure at the compressor flanges, taking into account pressure drops associated with these valves, flow elements, and piping.

Gemini Digital Twin User Interface

The Gemini compressor digital twin user interface includes:

- Compressor information configuration

- Process information configuration

- Performance Comparison

- Polytropic Head

- Polytropic Efficiency

- Shaft Power

- Discharge Pressure

- Pressure Ratio

Gemini Advanced Vibration Analysis

Accessing Vibration Data directly from the vibration monitor interface, the advanced vibration analysis tool provides best-in-class vibration evaluation without requiring a commitment to an Enterprise solution.

The Gemini system collects high-resolution compressor data by connecting to the compressor controls PLC and the compressor vibration monitoring system. The collected data is stored in an integrated "Edge" database, accessed by the Gemini application software, and presented in contextually relevant, easy-to-understand graphics.

Gemini Vibration Analysis General Features

- Single-Channel Analysis and Display

- Multi-Channel Analysis and Display

- Full-Train Analysis and Display

- Statistical Analysis and Alarm Setting

- Real-time and Historical Trending

- Time-Domain Waveform and Pivotal Trajectories Analysis

- Frequency Domain Analysis, including both stationary and non-stationary analysis

Gemini Vibration Analysis Interface

The Gemini vibration analysis hardware is typically mounted into the machine monitoring cabinet and connects directly to an existing Bently Nevada vibration monitor. No additional machine monitoring hardware is required.

The Gemini vibration analysis interface connects to the buffered Bently Nevada vibration monitor outputs using BNC coaxial cables and a BNC cable "aggregator" (supplied with the Gemini vibration analysis interface). The vibration analysis computer connects to the Gemini server using proprietary TCP communications.

Gemini Vibration Analysis Functions Include:

Time Based

- Single-Channel Analysis

- Multiple-Channel Analysis

- Full-Train Analysis

- Statistical-Analysis

- Real-time and Historical Status and Trending

- Time Domain Waveform and Pivotal Trajectories

Frequency Domain

- FFT Spectrum Analysis

- Waterfall Chart

- Full Spectrum Chart

- Full Waterfall Map (3D spectrogram in chronological order)

- Envelope Analysis

- 2D Dynamic Holographic Spectrum

- Subband Analysis

- BODE diagram

Time-Frequency

- Wavelet Analysis

- Short FFT analysis

- Empirical Modal Decomposition (EMD)

Gemini Remote Controls Monitoring

The Gemini remote controls monitoring application provides a remote user with the same compressor controls data in the same format as the data presented by the local human machine interface (HMI).

Using a "smart" device that supports a web browser, a remote user can access Gemini via the internet and monitor a given compressor like a local user without actually connecting to the local HMI.

After connecting to Gemini and accessing the Remote Controls Monitoring, you see the same data the operator sees on their local HMI, in the same context, using the same navigation and "drill-down," but without the ability to affect the compressor control.

Gemini Remote Controls Monitor Features

- Web-like internet access to the Gemini compressor performance monitor provides remote controls monitoring that is "graphically" identical (or nearly identical) to the local controls HMI, without actually connecting to the local HMI.

- Limited read-only and navigation access (no controller "writes." E.g., setpoint changes, start/stop pumps, etc.)

- Responsive graphics (the graphics resize appropriately to the smart device display)

- No remote client software is required apart from a standard internet browser

- Two-factor user-credential-authentication to prevent unauthorized access

Gemini Remote Controls Monitor Interface

The local Gemini server (with an individual IP address) is connected directly to the PLC that is controlling the compressor (and the associated driver and auxiliaries). Remote users can connect to the Gemini server using a standard web browser.

Once a remote user has connected to the Gemini application (with two-factor authentication), they are able to view the Gemini dashboard, the digital twin, the vibration analysis tool, and the "local HMI-twin" or remote control monitor using the Gemini application drop-down menu.